Product Category

Related Products

Online inquiry

Contact person: Mr.Jack Li

Tel: +86-577-88932893

Mobile: +86 13738392209

Skype: jackli2002

E-mail: sales@keeponmachinery.com

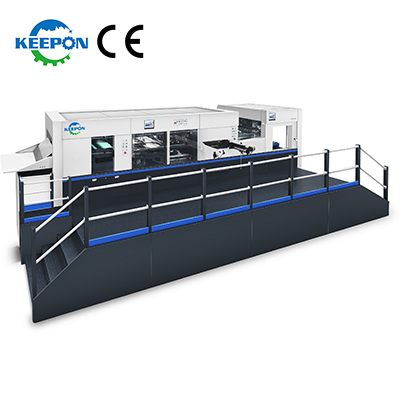

BHT-1060 Automatic Die Cutting Machine with Blanking And Stripping

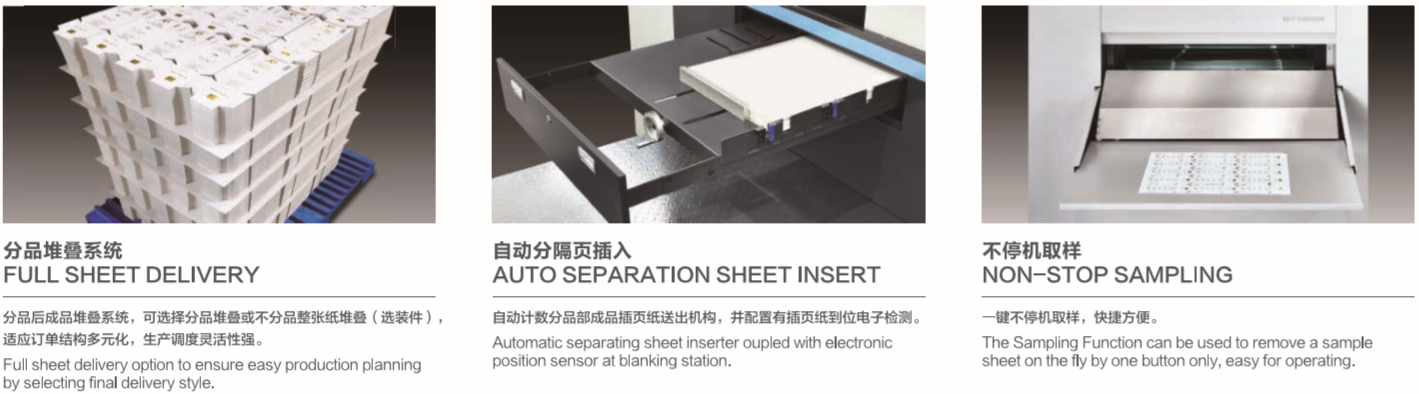

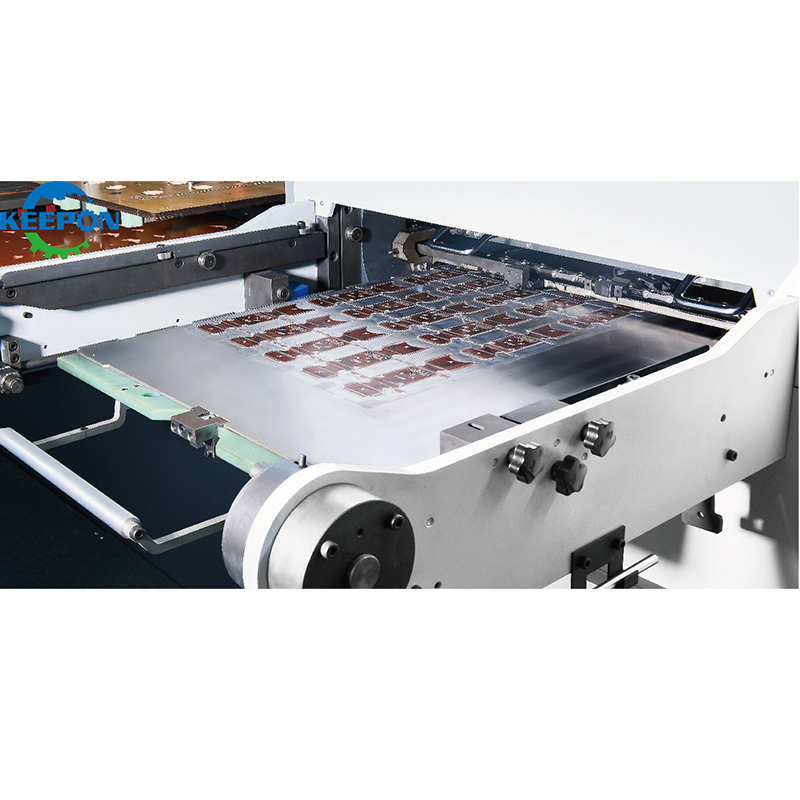

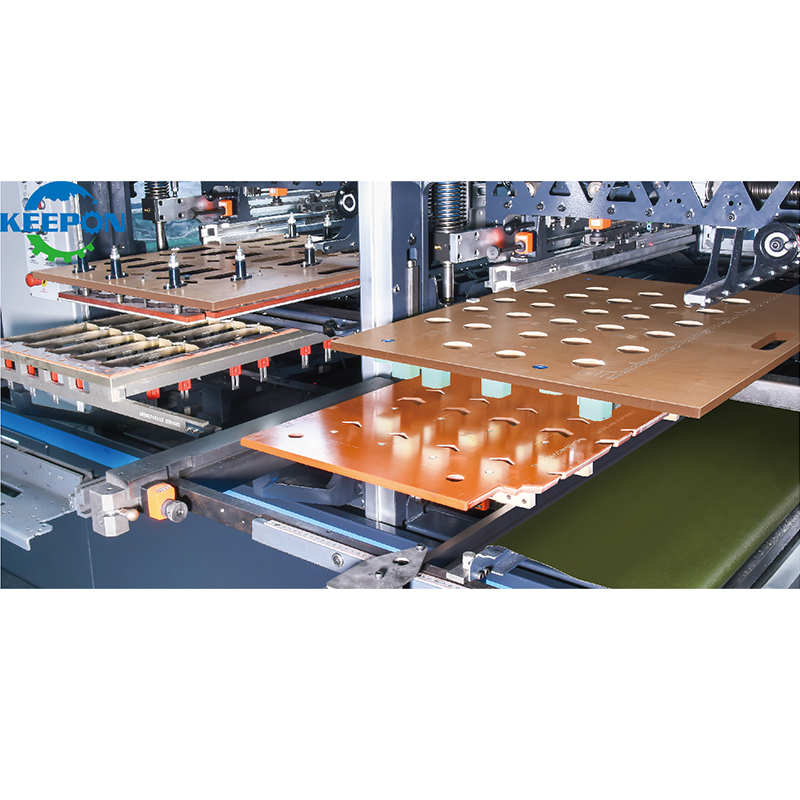

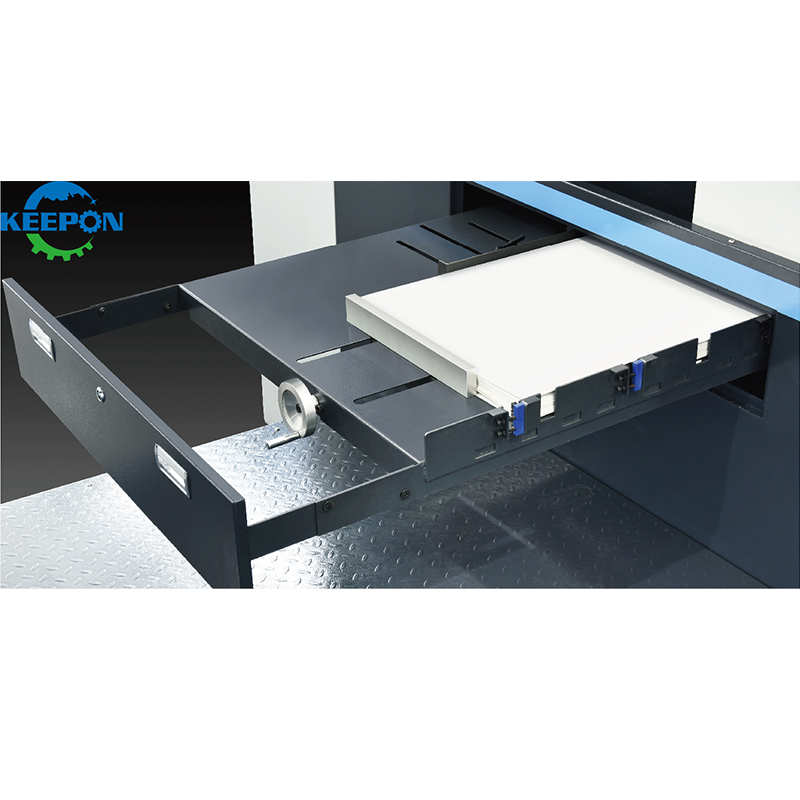

The BHT series Automatic Die Cutting Machine with blanking (Lead Edge Feeder) manufactured by Keepon Machinery. It can efficiently complete the die cutting and blanking of products, as well as maintaining the highest precision and product quality. This machine is well equipped and almost suitable for all die cutting requirements of products. It has advantage such as blanking stacker, auto separation sheet insert, Non-stop sampling, advanced plate lock up, double sheet detector etc.

| Product Detail | Online inquiry |

|---|

BHT-1060 Automatic Die Cutting Machine with Stripping and Blanking

The BHT series Automatic Die Cutting Machine with blanking (Lead Edge Feeder) manufactured by Keepon Machinery.It can

efficiently complete the die cutting and blanking of products, as well as maintaining the highest precision and product quality.

This machine is well equipped and almost suitable for all die cutting requirements of products. It has advantage such as blanking

stacker, auto separation sheet insert, Non-stop sampling, advanced plate lock up, double sheet detector etc.

Features:

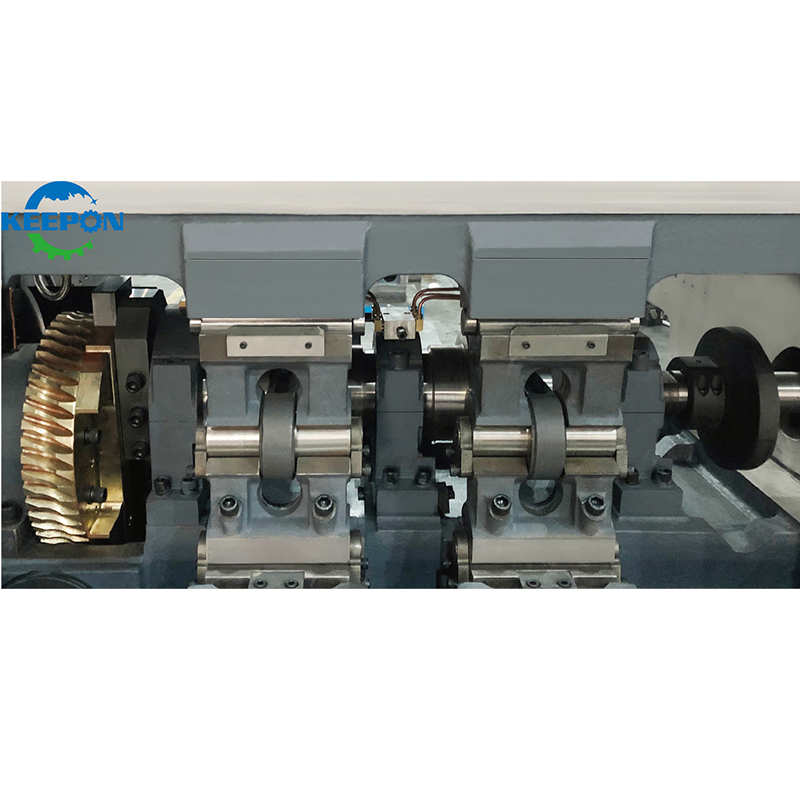

1. Adopt nodular cast iron-QT500-7, the mainframe wallboard casting by special technology process, thus featuring by high strength, never deformation and ensure the safety of the mainframe wallboard.

2. Adopt Taiwan-imported intermittent mechanism to ensure that the machine operates accurately. Also, the main engine is equipped with overload protection device and torque limit clutch,to ensure that when they being impacted by external force can stops immediately to reduce the damage to the machine body and teeth precision and reduce the occurrence of failure rate.

3. The machine uses NSK imported original bearing.

4. The whole machine uses original parts imported from Germany Moeller, and Japanese OMRON, etc.

5. Key parts of teeth row are imported from Japan.

6. The craft shaft is adopts Germany Ni-Cr-Mo metal steel, with high precision and will never deforms.

7. Equip with touch-screen operation interface in both Chinese and English.

8. Adopt Japanese SMC pneumatic components to ensure every pneumatic action performs accurately.

9. The front and side gauge adopts photoelectric system.

10. Each part of main machine is forced to adopts cycles lubrication system.

11. Siemens main motor ensures machine running stable.

Technical Specifications:

|

Stock Range |

Cardboard: 90-1000 gsm corrugated board: ≦4 mm Carton acceptable warp: 2% across |

|

Max.

sheet size |

1060x760 mm |

|

Min. sheet size |

400x350 mm |

|

Inner chase size |

1080x770 mm |

|

Max.

die cutting size |

1060x745 mm |

|

Min. gripper margin |

9-17 mm |

|

Cutting

rule height |

23.8 mm |

|

Min. Width of double cuts |

5 mm |

|

Max.

die cutting pressure |

300 ton |

|

Max.

mechanical speed |

7000 s/h |

|

Designed

max. mechanical speed |

8000 s/h |

|

Max. pile height at feeder-normal mode |

1800 mm |

|

Max. pile height at feeder-non stop mode |

1520 mm |

|

Max. pile height at delivery |

1580 mm |

|

Main motor power |

15 kw |

|

Total power required |

26 kw |

|

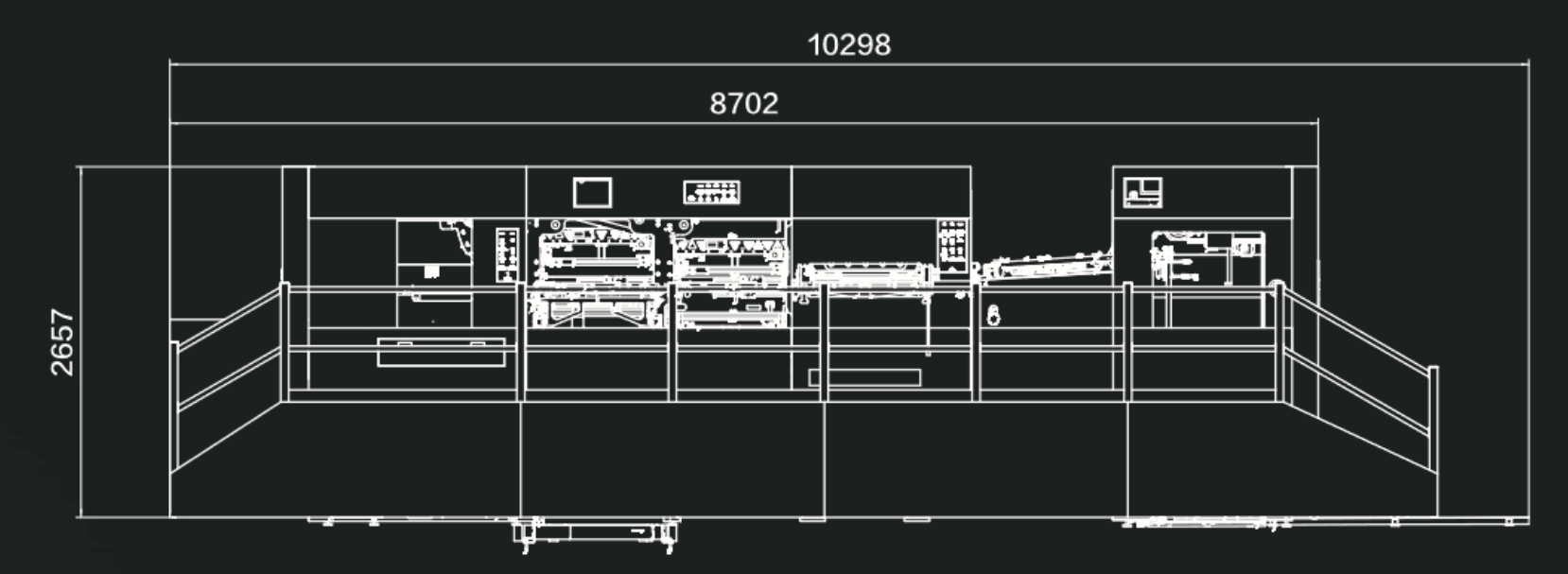

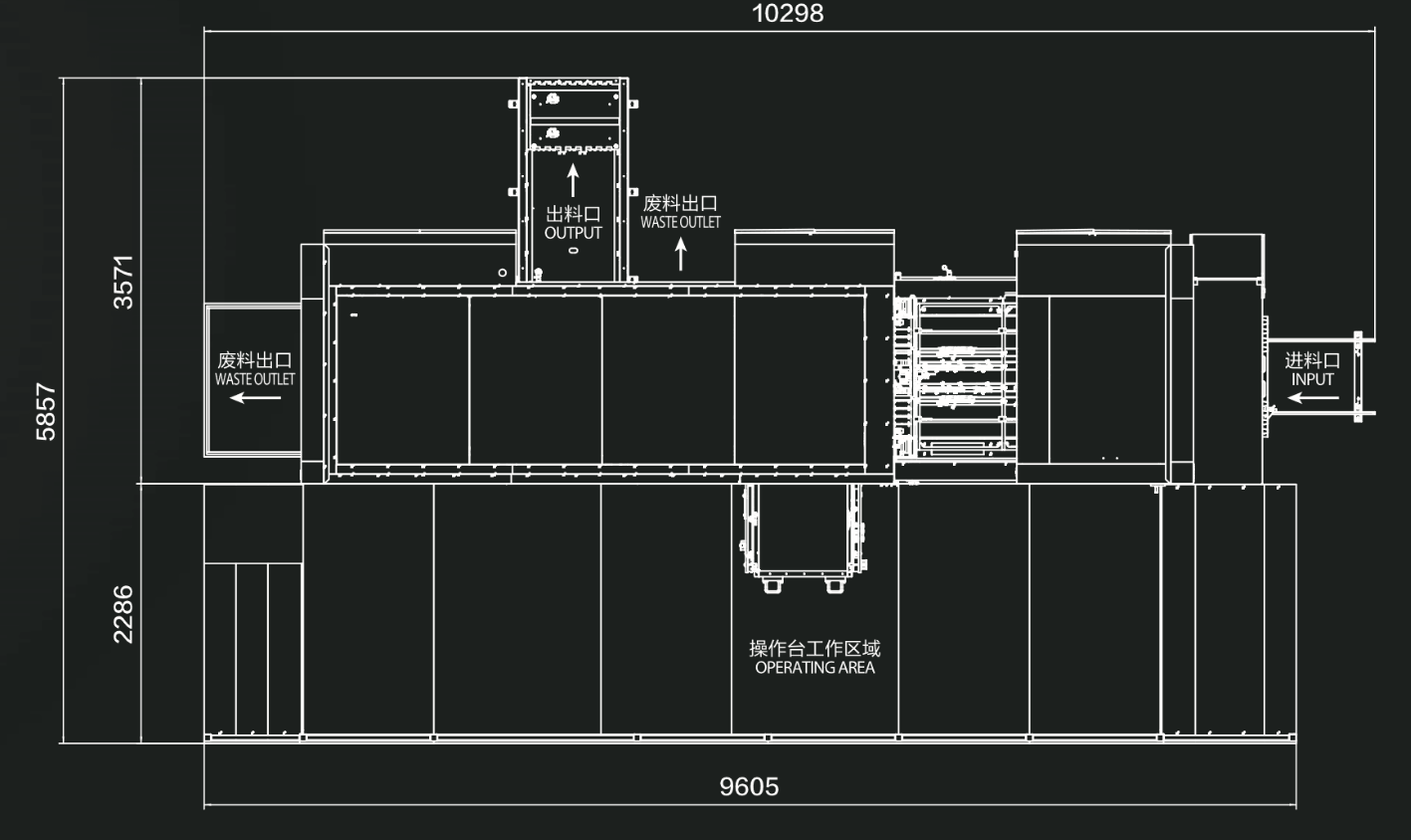

Machine

dimension |

10298(L) x 5857(W) x 2657 mm |

|

Machine

net weight |

22 ton |

Welcome to our website! Please feel free to send us your questions by asking us, we will contact you and provide you with the services as soon as possible. Please write in English.

E-mail Us

E-mail Us

WhatsApp

WhatsApp Video Link

Video Link

Youtube

Youtube